TPO roofing: everything you need to know

If you have seen a bright white roof, then you may be conversant with TPO Roofing. As one of the utmost communal roof types of big commercial conveniences, TPO has some of the superlative energy saving for single- ply membrane roofing!

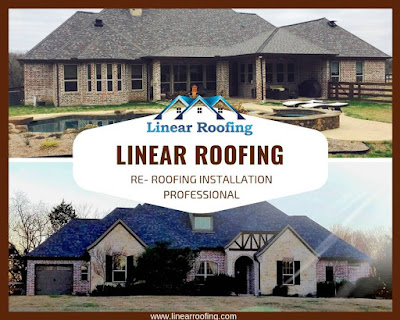

Here at Linear Roofing, we have been installing Single- ply Membrane roofing for over 30 years. In this blog, we cover everything you need to know about TPO Roofing.

WHAT IS TPO ROOFING?

Thermoplastic Polyolefin is a single-ply roofing membrane that is one of the wildest increasing Commercial Roofing Systems on the market. TPO roofing systems are made up of reinforcing scrim and single layer of synthetics that can be used to cover flat roofs.

TPO membranes are synthetic in sheets that are 12, 10 or 20 feet wide. These sheets are then rolled up and taken to the residential and commercial competence. TPO has protracted industry receiving with the ordinary meditative surface to reflect UV rays. As reported by the National Roofing Contractors Association (NRCA) TPO takes up about 60% of the commercial & Residential roofing market share.

TPO ROOFING Replacement & INSTALLATION

After prevailing substrate is prepared, either by removing or cleaning the existing roof, the insulation is installed. There are few types of insulation options the aptitude owner/manager can choose from:

- Polyisocyanurate (Polyiso)- The most used insulation type for Dallas roofingapplications, Polyiso is more exclusive but pay off with a higher R- Value rating.

- Extruded Polystyrene (XPS) – Frequently defined by the green, blue, green or pink color, XPS falls in between EPS and Polyiso in the range of price and performance. XPS is semipermeable with perm rating of 1.

- Expanded Polystyrene (EPS)- With the highest R- Value per dollar, EPS is used for roof, floor and wall insulation. EPS can be used with for ground contact and doesn’t retain water over time.

The TPO membrane can be committed to the cover board with a bonding mechanically or adhesive fastened. When the membrane is rolled out, the contractor then returns and uses a hot- air gun to hot air weld the seams together.

Read More: – North Texas Roofing Contractor Or Roof Inspection Dallas

Source Content

In its assembled state and used as a working platform, a framework to support wet concrete, construction material etc.Mainly used in cement, power plants and bulk material handling plants for Roofing constructions.

ReplyDeleteTPO roofing India

decking sheet manufacturers india

Nice post thanks for posting about steel manufacture, keep posting like this kind of content MS plate price in chennai is one of the top leading companies. They are best in supplying all types of steel for building construction.

ReplyDelete